As LCD vehicle displays have become more prevalent and versatile in both on- and off-highway, the time it takes to ensure proper display functionality after a software release has increased dramatically. It is not uncommon for displays to have 15, 20, or even 30 different screens, each of which having multiple sub-selections available. If you take into consideration different supported languages, the scope of the test grows dramatically. DISTek, as a company, is always attempting to define the future needs of customers in the off-highway industry, of which vehicle display testers are one of those needs.

I was fortunate enough to have the opportunity to work on one such display tester. Our client wanted a solution to simulate basic CAN communication to ensure proper functioning of the display, and to develop a system that could navigate to and test every screen, configuration option, and language that the display supported. This would allow them to run a series of tests overnight and come in the next morning to a completed test with pertinent result data and the only work the engineer had to do was press start. How would one complete such a daunting task you might ask? Well, that is exactly what I will be sharing with you in this series of blog articles.

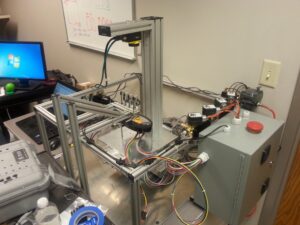

There were two different display types that needed to be tested by the system, each very different from one another, so versatility was going to be a requirement. We built a test fixture that was mounted to an XY table inside a frame with several pneumatic plungers on it. The display was then moved around using the XY table and the plungers were energized to press the various buttons on the display unit. A camera was mounted to the moving platform and suspended directly over the display providing a clear line of sight to the display screen. No additional lighting was required, as the display itself provided enough light for the camera to get a clear image from the display. The designed vision system was centered on the Cognex brand smart cameras and would also use the Cognex vision test development tool known as InSight Explorer.

The Cognex vision system was chosen due to the presence of a local supplier that could help with camera selection and provide us with everything necessary to build the vision system. Also, the InSight Explorer vision test development software they provided was completely free, which was a nice surprise when trying to complete this system on a strict budget. This allowed for the client to be able to make changes to the code in the future without having to contact us. With the InSight Explorer software being a free application, it is, unfortunately, somewhat lacking in documentation required considerable time to become efficient in its use.

My next blog post will focus on the vision system portion of the display tester, specifically targeting how to implement a Cognex vision test through the National Instruments LabVIEW software development environment. The post will read like a tutorial showing you how to use Cognex’s free InSight Explorer to write a vision test and how that vision test can then be implemented using LabVIEW. Stay tuned to find how you can create your own vision tests to support the growing need for vehicle display testers or to develop a vision system for any application you may come across.