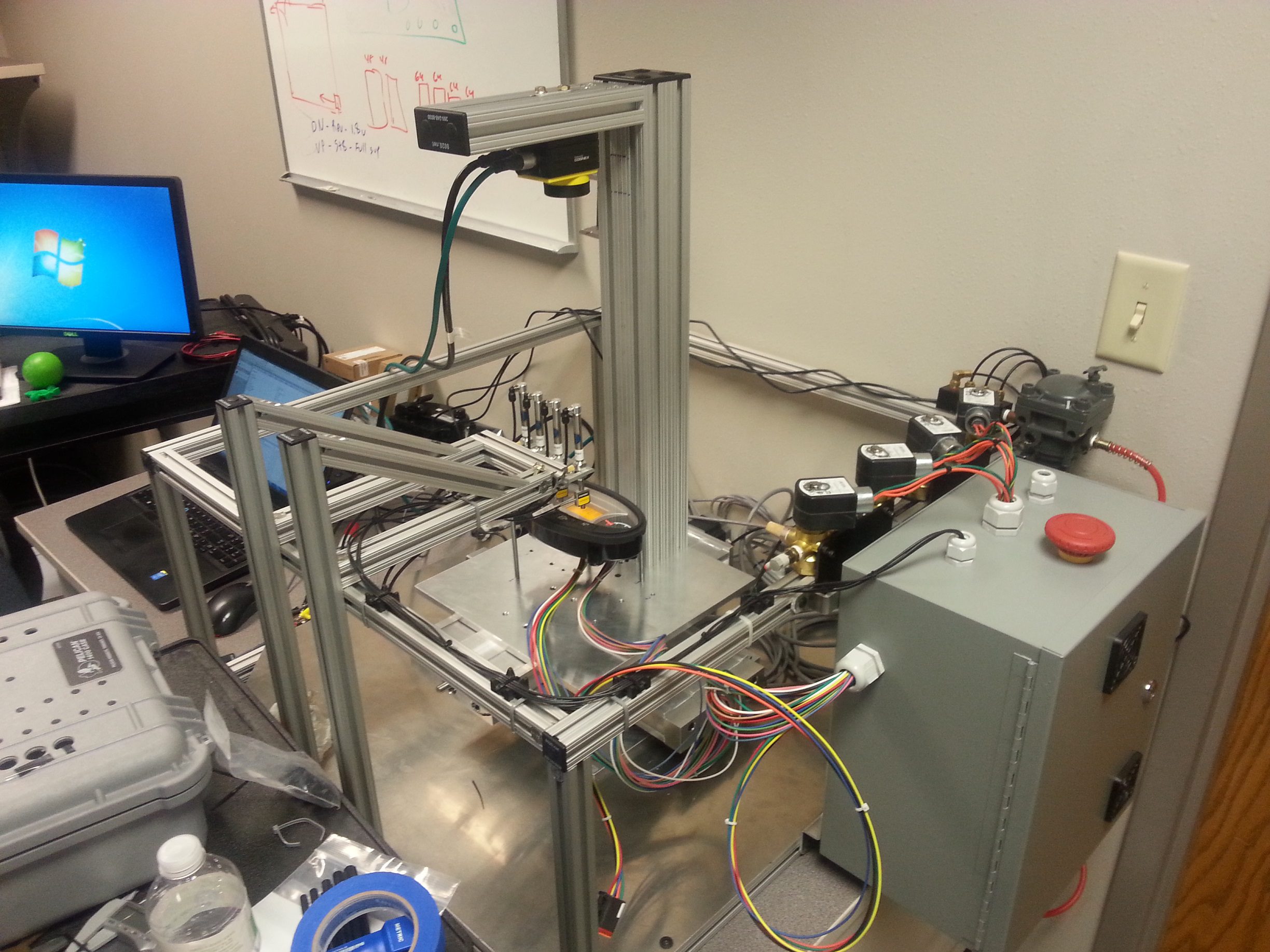

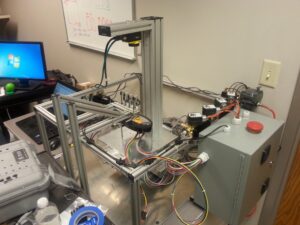

Full Steam Ahead: VT Anywhere

Between company shutdowns and working from home over the last few weeks, some organizations are slowing production and running into various struggles to keep moving forward. For DISTek’s VT Anywhere team, we have been getting even more done now than ever before. While Slack calls and meetings have completely replaced in person interactions, the team has remained focused and very productive.