Task Controller

ISOBUS Task Controller: Part 4

In Part 3 of my Task Controller series, I promised to get this Part 4 out close to the time of Spring Plugfest … and I missed by over a month. Regardless, here is Part 4.

In this Task Controller (TC) series, I have detailed data collection and variable-rate application. The final big feature of TC is Section Control. This feature also has an ISOBUS Functionality called TC-SC. Most people have an idea what section control is, but for the uninitiated … section control will turn on/off various controllable sections of an implement to avoid overlap in a field.

ISOBUS Task Controller: Part 2

In the last Task Controller (TC) post, I gave a broad outline of how a TC session works in the general case. In this post, I will start describing some of the different types of TCs and Tasks. These can range from very simple to very complex.

The simplest form a TC can take actually has an associated AEF Functionality associated with it: TC-BAS, which stands for Task Controller – Basic. With this type of TC, only totals are logged for a particular task.

ISOBUS Task Controller: Part 1

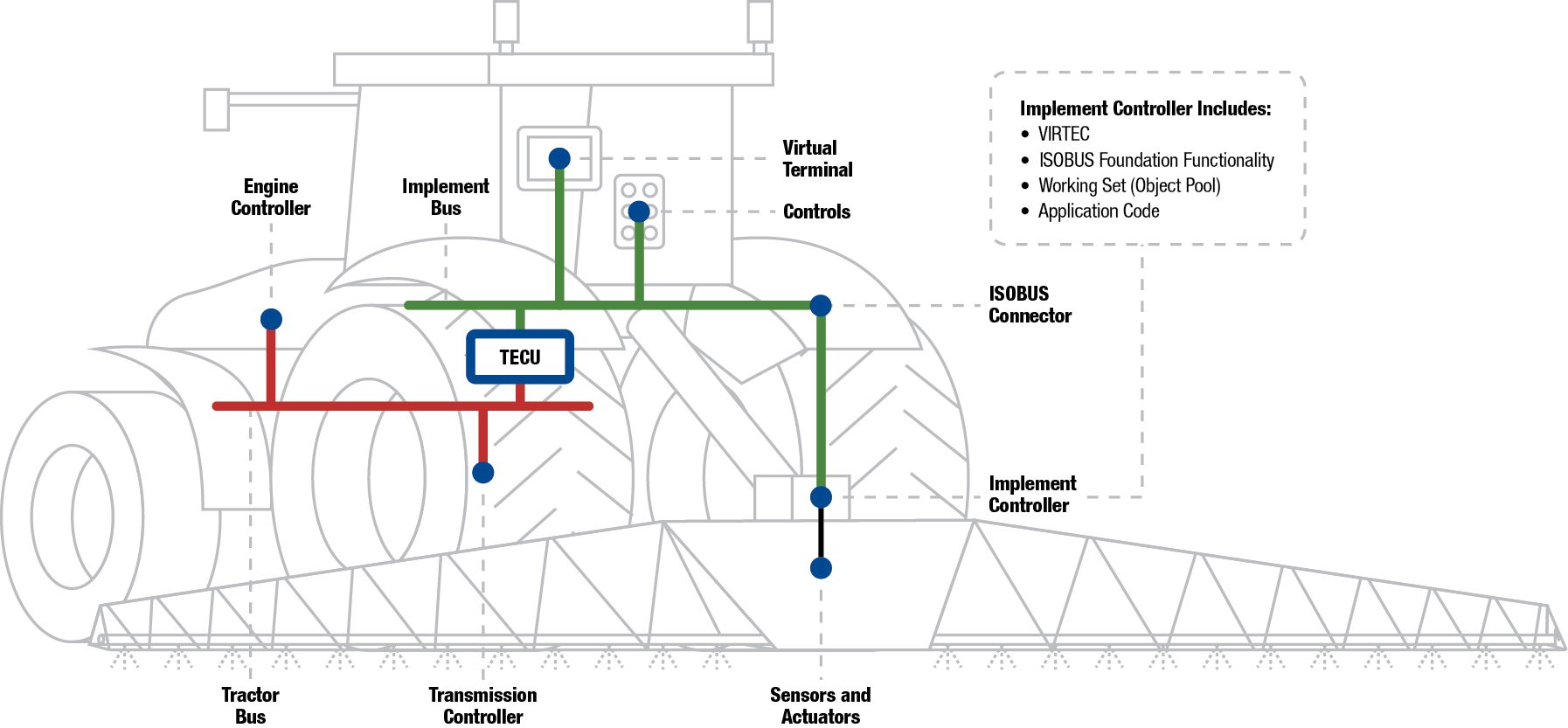

A few months ago in this blog I gave a very broad overview of Task Controller (TC). The Virtual Terminal is probably the best-known ISOBUS feature given its visual prominence, but TC is a popular topic to discuss in the ISOBUS world because it offers many intriguing possibilities … and seeks to fulfill many of the promises of precision agriculture across manufacturers. I thought it would be useful to spell out some of the details of TC as it can be a quite confusing subject. In this post, I will walk through the components and the steps of a typical TC session.

Introduction to Task Controller

Does anyone walk beans anymore? Early in my life, my dad’s three favorite herbicides for beans were my sister, my brother, and me. We spent many hours walking miles in the hot summer sun and learned many interesting plant names in the process: hemp dogbane, pigweed, velvetleaf, lambsquarter. Over the years it apparently became more economical to plant the beans closer together which made walking them nigh impossible, and my job morphed from walking the beans to driving the truck with the water and herbicides for filling the sprayer. Since I am less involved with the farm these days, I no longer know the costs of various chemicals, but I know even in the mid-90s that a small canister might go for $400. With inflation and the increased costs of raw materials, I am sure some of the chemicals are even higher cost now.

Every dollar saved in spray (or seed or fuel or …) is a dollar toward the bottom line profit, so naturally as these input costs go up the motivation to reduce waste of those inputs goes up. Technology has existed for quite some time to give farmers the ability to reduce waste with variable-rate-application and section control. But what has only more recently become available is the ability to integrate various manufacturers’ equipment together to achieve these technologies using ISOBUS. ISOBUS terminals have become increasingly common in tractor cabs to offer a nice GUI to the operator to manually control implements. With ISOBUS Task Controller, a single device in the cab can control the variable-rate or section control capabilities of an implement. Task Controller has the additional capability of recording data … either total data such as for a baler, or Geo-logged data as the implement is pulled through a field.

LIVE FROM SPRING PLUGFEST

Rookie no more, I’m two days into my first ISOBUS AEF Plugfest experience. It’s close to what I expected but as with all things I made some assumptions that turned out to be incorrect. No description or story of an event can fully prepare you for something, and Plugfest is no exception. That’s not to say what I’m about to share of my experience thus far won’t be of any help to future would-be attendees, so keep reading.